Welcome to Lithium Power, Inc. Your premier choice for cutting edge lithium battery design and manufacturing solutions. With unwavering commitment towards innovation, we are revolutionizing the energy storage industry one battery at a time. Our team of expert engineers and technicians deliver custom, high performance, reliable, and safe battery solutions tailored to meet your unique and demanding needs. Whether you require batteries for electric vehicles, renewable energy storage, or lead acid replacement, our state of the art manufacturing facility and rigorous quality control processes ensure every Lithium Power battery pack exceeds industry standards. Join us on the forefront of the energy revolution and unlock the true potential of lithium batteries with Lithium Power’s proprietary technology.

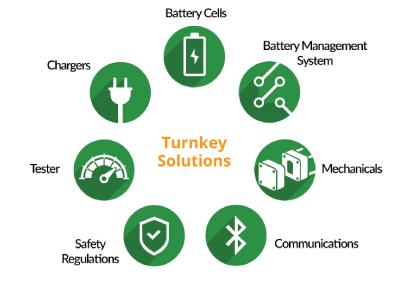

OUR UNIQUE BATTERY TECHNOLOGY BREAKTHROUGHS

- Drop in replace lead acid batteries

- UN, IEC, UL safety certifications

- Proprietary BMS with multi-level protection parameters

- Cell and pack balancing for parallel scalability

- User configurable battery settings

- Remote monitoring and management

- Intelligent BMS with communication ability

- Robust IP rated mechanical design