- Executive Summary

- Overview of LTO battery technology

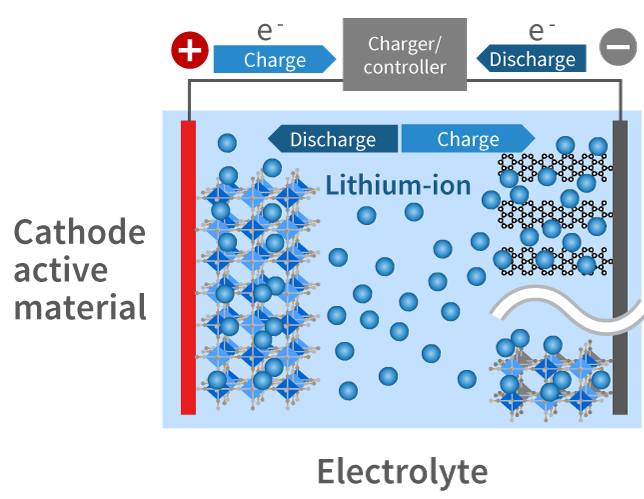

- LTO (Lithium Titanate Oxide) batteries are a type of lithium-ion battery that uses lithium titanate as the anode material. The cathode is typically Lithium Manganese Oxide (LiMn₂O₄), and the electrolyte consists of a lithium salt dissolved in an organic solvent, similar to other lithium battery chemistries. The main difference is the titanate. Titanate is produced from titanium, which is processed to create titanium dioxide through various methods. This lithium titanate anode has an exceptionally large surface area, resulting in faster charging and discharging.

- Relevance in solar and ESS markets

- LTO’s high power density makes it ideal for stationary uses like ESS and solar, where long cycle life, fast charging and discharging, and a wide temperature range are crucial.

- Summary of key findings and recommendations

- With LTO in ESS/Solar applications, the owner can expect an exceptional cycle life. When properly configured, it can anticipate up to 20,000 charge/discharge cycles. This results in a very low cost per cycle. Considering the savings in battery replacement, service costs, operational uptime, and peace of mind, LTO offers a strong advantage over other battery chemistries available today.

- Overview of LTO battery technology

- Introduction

- The growing need for robust energy storage in renewable energy systems

- Energy storage needs are everywhere you look. They are so essential and unnoticed that most people go through their day unaware of their impact or the widespread presence of simple

batteries that improve their lives. - With energy demand rising due to EV adoption and the increasing importance of electrified devices and applications, the grid struggles to keep up. Batteries play a crucial role in managing fluctuations in energy use. They charge and store energy when demand peaks during the day and release it when demand is highest in the evening and at night, helping the system recover.

- Energy storage needs are everywhere you look. They are so essential and unnoticed that most people go through their day unaware of their impact or the widespread presence of simple

- Challenges with existing battery technologies in solar + ESS

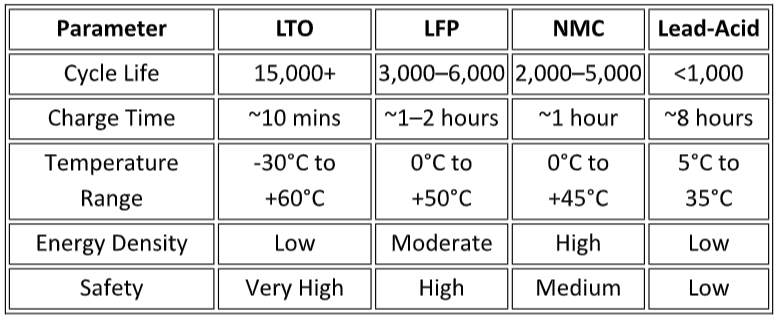

- Lithium ION (NMC/LCO/NCA), while very energy dense, has several disadvantages in ESS/Solar applications. Its relatively short cycle life, limited temperature range, and lower power density make it less suitable for most ESS/solar uses. The volatility of chemistry, especially under extreme conditions, should not be underestimated.

- LFP (LiFePO4 Lithium Iron Phosphate) shows strong potential in many ESS and solar applications. It offers good power density, a longer cycle life, a wider temperature range, and a competitive cost, which secures LFP’s solid market position. However, compared to LTO, it falls short in nearly every aspect except for initial cost. LFP is now very price competitive, approaching the cost per kilowatt-hour of some lead-acid batteries.

- The growing need for robust energy storage in renewable energy systems

- LTO Battery Technology Overview / Introduction to LTO chemistry and its potential impact

- 3.1. Chemistry and Structure

- Composition (Li₄Ti₅O₁₂ as anode material). The following is a basic diagram of Toshiba’s SCiB™ battery and how it works.

Source: www.toshiba-clip.com/en/detail/p=752

- Composition (Li₄Ti₅O₁₂ as anode material). The following is a basic diagram of Toshiba’s SCiB™ battery and how it works.

- 3.2. Primary Performance Characteristics

- Ultra-fast charging capabilities

- High cycle life (15,000+ cycles)

- Wide temperature tolerance (-30°C to +60°C)

- Intrinsic safety and thermal stability

- Wide variety of cell form factors

- High Power Density

- 3.3. Drawbacks and Limitations

- Lower energy density (2.5V nominal/cell)Higher upfront cost

- Supply Chain availability when compared to other mass-produced Lithium battery chemistries

- Limited supplier options when compared to other mass-produced battery chemistries. However, with LTO being offered by companies like Toshiba, Microvast, Saft, Nichicon, Leclanché, Altairnano, Yin Long, and LTO Battery Co., LTO remains available worldwide.

- 3.1. Chemistry and Structure

- Use Case Scenarios in Solar + ESS

- 4.1. Residential Solar Systems

- Daily cycling and fast charging needs

- Allows for using a smaller capacity battery to perform the same work as a larger, low-efficiency

battery.

- Allows for using a smaller capacity battery to perform the same work as a larger, low-efficiency

- Benefits for off-grid and backup power systems

- Ideal for applications that are strictly recharged by either solar, wind, or some other energy supplied by nature.

- Imagine a battery with twenty+ years of life providing energy on demand and in an emergency.

- Daily cycling and fast charging needs

- 4.2. Commercial & Industrial Applications

- Peak shaving and load shifting

- To learn about these essential energy-saving techniques and protocols, please consult the expertise of Facilities Dive by following this link – https://www.facilitiesdive.com/spons/what-every-industrial-facility-manager-needs-to-know-about-peak-shaving-and/725725/

- Energy resilience and critical infrastructure support

- For detailed information on this subject, the curation and reference in this article from the US Department of Energy are invaluable resources. https://www.energy.gov/ceser/energy-threat-analysis-center-0

- Peak shaving and load shifting

- 4.3. Utility-Scale Storage

- Grid balancing and frequency regulation

- Many electrical devices rely on a stable and predictable power supply and electrical frequency. Grid balancing and frequency regulation are central for maintaining the stability and reliability of the electrical grid, ensuring there is a constant balance between electricity supply and demand. This involves continuously matching electricity consumption with generation to keep the grid’s frequency within a narrow range, usually 50 or 60 Hz, depending on the region. Deviations from this frequency can lead to instability and even blackouts. A good article on this subject can be found here – https://www.atlanticaenergy.org/balancing-the-grid-101/#:~:text=What%20is%20electrical%20grid%20balancing,for%20up%20to%20two%20hours.

- Long-life storage for remote solar farms

- Solar farms are being built on an ambitious scale. Everywhere you look, a new solar farm is coming online. To make these efforts fully effective, LTO batteries play a crucial role. It’s simple: these solar farms only produce energy when the sun is shining. Storing some of that energy during the day and making it available at night allows solar power to be most effective and efficient in generating and storing the sun’s energy.

- Grid balancing and frequency regulation

- 4.4. Microgrids and Off-Grid Systems

- Harsh environment suitability

- LTO is a durable battery chemistry! It handles high rates of charging and discharging, works well in extreme temperatures, and even when those limits are exceeded, it recovers safely with minimal degradation.

- Modular, scalable deployments

- Well-defined LTO building blocks or modules are available from several manufacturers. From micro cylindrical cells from Nichicon to large prismatic cells from Saft and Toshiba, to big cylindrical cells from Yin Long, and pouch cells from Microvast, LTO cell form factors come from a variety of suppliers. These shapes and sizes allow LTO to succeed in many applications where footprint, volume, storage, and cost are key for successful use.

- Harsh environment suitability

- 4.5. Other Potential Applications for LTO:

- Wide range of EV applications – bus, truck, heavy-duty excavation vehicles, and more.

- Vehicle Starter Battery

- RV (operational)

- Marine (operational)

- GSE (Airport Ground Support vehicles)

- Car/Boat Audio

- AMR (Autonomous Mobile Robotics) & AGV (Autonomous Guided Vehicle)

- Forklift (especially in a 24/7 cold storage warehouse or outdoor application)

- Aerospace and Defense applications

- 4.1. Residential Solar Systems

- Comparison with Other Chemistries

- 5.1. LTO Safety

- Every battery chemistry carries some risk, even alkaline and lead-acid ones. The key to minimizing these risks begins with selecting the right chemistry for the application from the start. Not only will safety be improved, but the chances of successfully deploying the device can also depend on choosing the best, most suitable battery.

For a comprehensive understanding of the safety aspects of LTO, especially Toshiba, reviewing this overview is essential. https://www.global.toshiba/ww/products-solutions/battery/scib/about-scib/about.html#:~:text=Six%20outstanding%20features,as%20refilling%20a%20gasoline%20car

- Every battery chemistry carries some risk, even alkaline and lead-acid ones. The key to minimizing these risks begins with selecting the right chemistry for the application from the start. Not only will safety be improved, but the chances of successfully deploying the device can also depend on choosing the best, most suitable battery.

- 5.1. LTO Safety

- Economic Considerations

- 6.1. Capital Expenditure vs. Operating Expenditure (Cost)

- Initial cost comparison

- LTO should be viewed from a value perspective rather than just an upfront cost per kilowatt comparison. Simple applications and devices with a predictably short lifespan of less than five years are not ideal use cases for LTO as a battery power or storage solution. When considering LTO, one must expect the device’s longevity not to be quickly overtaken by future technologies or anticipated advancements that could make the device obsolete. LTO is best suited for applications that are “in it for the long haul.” Like most technologies, it’s important to consider all factors when choosing a battery chemistry and form factor best suited for the work at hand. Education, research, and leaning on trusted experts in the field are key to the proper and successful implementation of the battery and the device it is powering or storing energy. *Contact a Lithium Power (LPI) expert today to learn more about LTO and other battery chemistries!

- Total cost of ownership (TCO) over 10–20 years

- When paired with the right application, the long-term advantages of LTO are clear. Considering over 15,000 cycles, operation in almost any temperature or environment, and the ability to quickly recover from moderate abuse, the overall safety features of LTO make it a strong choice for many applications that need a durable battery solution. And when the battery is finally depleted, LTO is one of the easiest chemistries to recycle.

- Initial cost comparison

- 6.2. Return on Investment (ROI)

- Value of long cycle life and low maintenance

- LTO should be considered for its long cycle life. If the application requires decades of durability, then the ROI of LTO becomes a key factor. Less maintenance results in fewer technician service calls, leading to significant savings in time and money.

- Application-specific cost-benefit analysis

- Summary Table: (Generated by Gemini AI search)

Feature NMC Batteries LFP Batteries LTO Batteries Energy Density 150 – 250 Wh/kg (up to 300 Wh/kg) 90 – 160 Wh/kg (up to 205 Wh/kg) 60 – 120 Wh/kg Cost Approximately $100-$130/kWh for packs; higher for specialized applications Currently around $70-$100/kWh; projected to drop to $36-$56/kWh by 2025 Approximately $150-$200/kWh due to specialized materials Applications Electric vehicles Renewable energy storage Fast-charging stations

**Represents raw cell cost. Pack design, features, and will greatly impact the actual price.

- Summary Table: (Generated by Gemini AI search)

- ROI Conclusion:

For a 20-year ESS application, LTO batteries, despite their high initial cost, may be the most economical choice in the long run due to their extremely high cycle life and lower maintenance needs. LFP batteries offer a good balance of cost and performance, making them a practical option if budget is a major consideration. NMC batteries, while suitable for applications requiring high energy density, tend to be more expensive and need more frequent replacements over 20 years compared to LTO and LFP. Ultimately, the best choice depends on the specific needs of the ESS application, including energy demands, desired lifespan, and budget.

- Value of long cycle life and low maintenance

- 6.1. Capital Expenditure vs. Operating Expenditure (Cost)

- Future Outlook and Technological Advancements

- Innovations to improve energy density

- A continuous stream of research is being carried out by corporations, government agencies, universities, and think tanks to improve LTO batteries. Progress in all areas makes LTO a promising and dynamic battery option for decades to come.

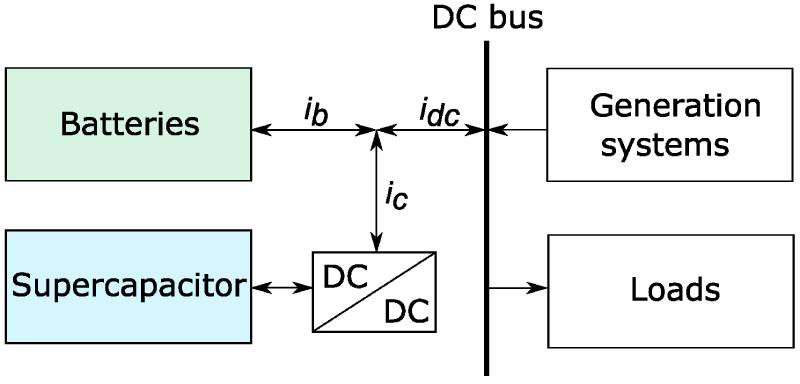

- Hybrid battery systems (e.g., LTO + supercapacitors)

- Some companies have adopted hybrid and innovative battery designs that incorporate super-capacitors. These super-capacitors deliver an instant surge of current needed for specific applications. Once the current stabilizes, the main battery takes over, and the super-capacitor is recharged from the battery. In regenerative charging systems, the super-capacitor serves as an energy buffer, helping to dissipate heat and store energy.

Here is a diagram of a simple system:

- Some companies have adopted hybrid and innovative battery designs that incorporate super-capacitors. These super-capacitors deliver an instant surge of current needed for specific applications. Once the current stabilizes, the main battery takes over, and the super-capacitor is recharged from the battery. In regenerative charging systems, the super-capacitor serves as an energy buffer, helping to dissipate heat and store energy.

- Market trends and projected adoption rates

- The future of the LTO market and its adoption looks promising. All signs point to LTO continuing to expand into applications that leverage its many unique features. Identifying and entering those markets is key. Education and training will be vital for LTO’s long-term success.

- This executive summary of a report from www.Marketsandmarkets.com will provide even greater clarity on the future of LTO – https://www.marketsandmarkets.com/Market-Reports/lithium-titanate-oxide-lot-battery-market-161263677.html#:~:text=%5B183%20Pages%20Report%5D%20The%20global%20Lithium%20Titanate,CAGR%20of%2010.1%25%20from%202023%20to%202028.&text=The%20growing%20hybrid%20.

- Regulatory and policy implications

- Like all Lithium batteries, LTO is regulated by the UN and IATA and classified as dangerous or hazardous goods. UN38.3, testing and certification, remains in effect with no change. The testing required for UN38.3 is as follows, and all LTO batteries must adhere to safe shipping and handling practices.

- Altitude Simulation (T1): Tests performance at high altitudes.

- Thermal Test (T2): Evaluates stability at extreme temperatures.

- Vibration (T3): Assesses resilience to transport-related vibrations.

- Shock (T4): Tests the battery’s ability to withstand impact.

- External Short Circuit (T5): Evaluates safety mechanisms under short-circuit conditions.

- Impact/Crush (T6): Assesses mechanical stress tolerance (for cells).

- Overcharge (T7): Examines protection against overcharging (for rechargeable batteries).

- Forced Discharge (T8): Tests safety under forced discharge conditions (for cells).

- LTO packs and systems might need additional testing according to standards set by UL, IEC, and SAE. There are also many country-specific certifications that could be necessary. Please check with the regulatory agency in the country you’re asking about, or contact LPI, and we will help you navigate the complex rules and regulations.

- Innovations to improve energy density

- Conclusion

- Summary of LTO’s role in enhancing solar + ESS systems

- There is little doubt that LTO will play a long and successful role in ESS and solar-charged applications for decades to come. Advances in every part of the battery (anode, cathode, separator, electrolyte), manufacturing methods, and pack design will deliver the benefits the world needs as the use of renewable energy storage devices and systems continues to grow. Eventually, these ESS and solar systems and the batteries that accompany them will become as common as the sun and wind that power them.

- Key takeaways: reliability, longevity, safety

- LTO and the companies that produce them have demonstrated resilience and the ability to be long-term players in the battery industry. Developing new markets and ventures across the USA and worldwide will be vital for their staying power, not just to participate in the battery industry, but to succeed.

- Strategic recommendations for adoption

- Summary of LTO’s role in enhancing solar + ESS systems

Contact LPI! We will help you scope out the application and recommend the best solution for your specific needs. Like all battery technologies, LTO has its unique features but also presents challenges. LPI will guide you through this design process and provide the answers you need for cell selection, pack design, and manufacturing, ensuring a timely and cost-effective outcome.

About Lithium Power, Inc.

LPI employs AI tools throughout the entire process to create battery solutions that power AI-driven devices.

An elegant and wonderfully conceived model for success.

LPI is your top choice for advanced lithium battery design and manufacturing solutions. From start to finish, including battery end-of-life, LPI utilizes AI tools and innovative processes, combined with a strong focus on personalized customer service in a traditional manner. LPI is leading the transformation of the AMR and AGV industries, one battery at a time. Our expert engineers and technicians deliver custom, high-performance, reliable, and safe battery solutions tailored to your specific, demanding requirements and designed to pass even the strictest certification tests.

LPI’s advanced manufacturing facility and rigorous quality control procedures ensure that every Lithium Power battery pack exceeds industry standards.

Join us on the energy revolution journey and discover the true potential of lithium batteries in your applications with Lithium Power’s proprietary technology and commitment to excellence.

OUR UNIQUE BATTERY TECHNOLOGY BREAKTHROUGHS

- Proprietary BMS with multi-level protection parameters

- Drop-in replacement lead-acid batteries

- UN, IEC, and UL safety certifications

- Cell and pack balancing for parallel scalability

- User configurable battery settings

- Remote monitoring and management

- Intelligent BMS with communication ability

- Robust IP-rated mechanical design

References/Sources

- Technical publications, whitepapers, and industry reports

- Manufacturer datasheets

- Academic research on LTO advancements

- Gemini AI search

- Toshiba Battery

- ComEd & PG&E

- Echandia

- Atlantica Centre for Energy

- Facilities Dive

- US Dept. of Energy

- Microvast

- Saft

- Nichicon

- www.marketsandmarkets.com